Lubrizol provides industry-leading materials, trusted regulatory guidance, and product development support from ideation to commercialization. Our medical grade polymers are specifically formulated for superior biostability, biocompatibility and processing versatility. We offer a full range of medical grade thermoplastic polyurethane (TPU), ideal for use in cardiology, urology, vascular, wound care and many other applications. We provide differentiated design, development and manufacturing services of components, subassemblies and finished devices. Our expertise is aligned with minimally invasive catheters and delivery systems as well as a broad array of silicone-based medical devices; as well as thermoplastic and silicone processing.

Lubrizol offers full lifecycle capabilities, an integrated approach, and a partner that can provide a path towards medical device excellence.

Providing polymer solutions for short and long term implantable cardiovascular applications, including guidewires, delivery systems, and pacemaker headers and leads.

Providing medical grade thermoplastic polyurethanes ideal for oral devices such as dental aligners, retainers, mouthguards and orthodontic elastics.

Offering Pathway™ thermoplastic polyurethane (TPU) excipients for controlled, sustained drug release in biodurable implants and combination products.

Offering excellent oxidative stability for long-term blood contact applications, these aliphatic and aromatic polycarbonate TPUs are available in natural and radiopaque formulations.

Ideal for medical device applications requiring flexibility and strength, these aromatic polyether and polyester TPUs are recognized for their history of use in medical applications

Designed for superior physical performance, these aromatic polyethers are available in natural, radiopaque and custom colors.

Formulated for durability, these rigid aromatic polyurethanes exhibit superior toughness, impact, abrasion and chemical resistance.

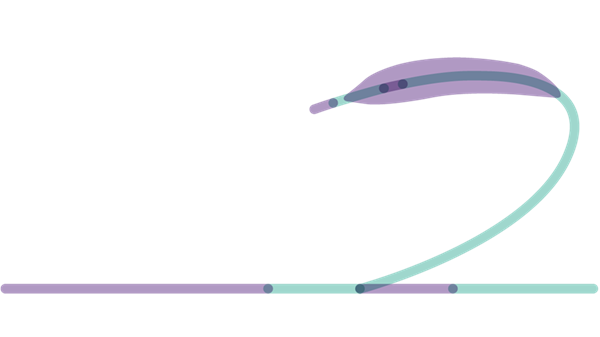

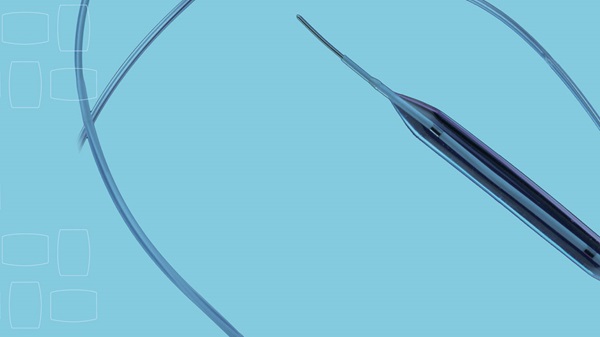

Specializing in the design of innovative devices, including drug coated balloons, catheter shaft assemblies, and complete delivery system designs, as per your product requirements.

Our team of experienced extrusion and catheter engineers closely collaborate with our customers to develop catheter shaft/catheter assemblies that meet application–specific requirements.

![]()

Providing a full range of services, such as extrusion, insert molding and encapsulation, bonding and reinforcing, and other medical assembly techniques to prepare our customers' medical devices for market.

Expertise in tight-tolerance silicone and thermoplastic medical extrusions, specializing in multilumen profiles and complex geometries for your tubing needs.